Choosing the Best Sensor Cable Types

admin

- 0

Choosing the Best Sensor Cable Types

Sensors have different pin configurations. This means that the right cable must match the pin configuration of the sensor. The types of cable available include PVC, TPE, and PUR. Push-pull connectors are also available. For the best results, use a cable with the same number of pins as the sensor.

PVC

PVC Sensor cable is a type of cable that is used for connecting sensors and actuators. It is available in different jackets and with different specific options. Choosing the right jacket is important, as it can make the cable last longer. However, before you make your decision, you should know a few things about the different jackets.

There are two main types of PVC cable. The first one is the General Purpose PVC cable. This cable is available widely and is best suited to low-voltage applications. It is also resistant to salt and moisture. PVC cables have good insulating properties and can withstand low-to-medium mechanical stress. This cable type can be non-oil or oil-resistant.

PUR

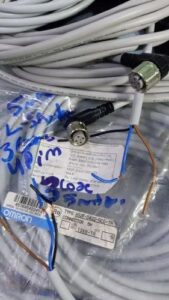

There are two common PUR sensor cable types. One has an M12 female connector, the other is a 4-pin M12 male connector. Both have an IP67 rating and are able to resist oil. Whether you need to use the cable for a single or multiple sensors, there are cable types to fit every need.

Sensor cable jackets are made of different materials. There are PVC, TPE, and PUR. Each material has its own benefits and drawbacks. PVC is a common material for general-purpose applications. It is also resistant to moisture, which makes it a good choice for wash-down applications.

TPE

There are different types of cables and the material that makes up the cable determines its usefulness for a specific application. The most common materials used in industrial applications are PVC, TPE, and PUR. PVC, or polyvinyl chloride, is a durable material. It’s a good choice for applications that are not too critical. TPE, or thermoplastic elastomer, is a rubber compound. This material is able to withstand high temperatures, shocks, and all types of weather. It is also suitable for industrial settings, such as the food industry.

Polyethylene (PE) cables have excellent electrical properties. They are also exemplary in terms of insulation. However, they can be stiff and hard. For this reason, it is better to choose cables with a lower density. These cables are also flexible and have exemplary weather and moisture resistance. They’re also excellent for harsh environments and exposed work applications. The electric qualities of polyethylene can be enhanced by cross-linking, making them more flexible and resistant to cuts and solvents. They’re also suitable for a variety of temperature ranges, from -65 to 80 degrees Celsius.

M12 push-pull connectors

The locking M12 push-pull connector is a new standard. It provides the advantages of the screw-type connector but without the additional tooling required for screw-locking. It is also suitable for applications with limited space. It is important to consider the application requirements, installation environment, and operating conditions before selecting a connector type.

Push-Pull connectors are ideal for applications that require high density and low-profile cabling. They are compact, feature an integrated locking system and are reliable and safe to use. M12 connectors are available in both male and female versions. Their unique locking system eliminates twisting connectors, reducing the risk of intermittent connections.

The push-pull configuration has gained popularity in the industrial market. Earlier versions of these connectors required the installation of adapters and secondary components, which were complicated and time-consuming. Today, push-pull connectors are compatible with a variety of sensors and devices.

M12 connectors can be used in industrial applications, and are designed to be reliable and rugged. They are available with three, four, five, and eight pins, and can be locked for increased security. These connectors are widely used in factory automation applications. They are used to connect sensors and actuators, and can also deliver power.

Miniature versions of the M12 connector are popular for use in industrial settings. They can also be used for power and network sensors. The M12 connector’s design can be modified to support different protocols, such as PROFIBUS.

OD cable

There are 3 types of cables for OD sensors: Type 1, Type 2 and Type 3. Each has specific characteristics. For example, Type 3 cables are marked with the “Type 3” imprint, while Type 2 cables do not have any identifier. If the cable is to be bent within five cm, the right angled connector cable is recommended. For proper functionality, a minimum voltage of 9.5 V must reach the sensor. If the sensor voltage falls below this value for even a second, the sensor is not functional.

When choosing the right OD sensor cable, you should take into account the pin number of the sensor. The number of pins varies between sensors, and the cable must match. The sensor’s manufacturer will indicate which wire color corresponds to the input and output functions. This is to avoid confusion and to ensure accurate measurements.

The temperature and voltage of the sensor are also major considerations. Other features include flexibility and abrasion resistance. Chemical compatibility is also critical, so you should choose the proper material. In addition, the cable should be designed to be able to withstand the pressure changes caused by abrasion.

Sensors used in demanding applications must be durable and meet stringent quality standards. They must also be light and small. Sensors used in military and aerospace applications must be highly reliable and have low off-gassing. Other demanding environments include automotive, industrial and medical applications.

Signal splitter

A good quality signal splitter will have a small to no reflection from the input port to the output port. If there is a reflection, it will be due to a bad splitter. If you observe reflections from both the input and output ports, the splitter must be replaced. Otherwise, a high-quality splitter should have only a single reflection, and low-quality ones may not show any reflection at all.

Signal splitter cable types come in different sizes and types. If you have two or more devices connected to your home theater, you can choose between two or four types to suit your needs. A good quality splitter is made of a durable, corrosion-resistant material. This will help you get the best performance from your splitter. In addition, a high-quality splitter will operate quietly. There are four types of signal splitters: passive, multi-switch, diplex, and active. Each of these has advantages and disadvantages.